Jewellery Laser Welding Machine

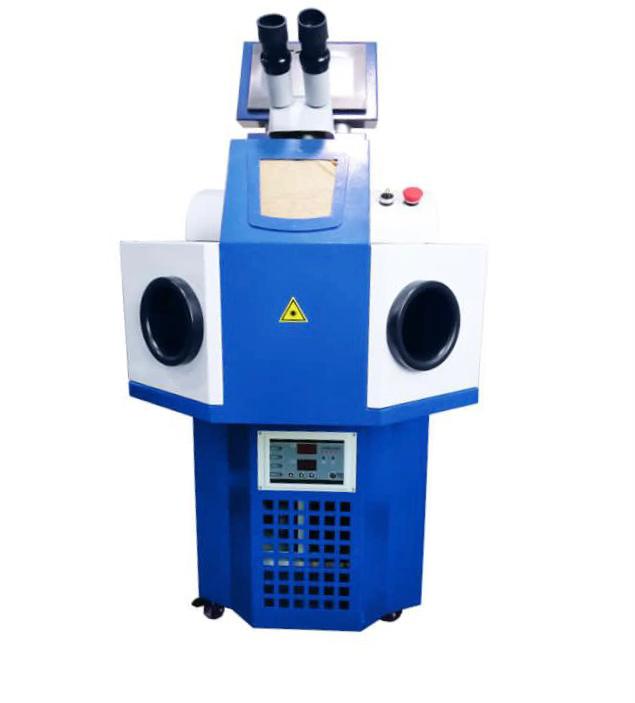

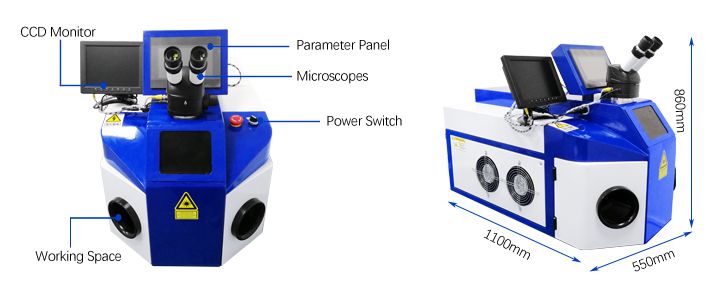

Jewellery laser welding machine – Desktop Model

1. Red point fast positioning, CCD display, microscope optional.

2. Adjustable working table allows welding from small size to big size of work piece.

3. Fast working speed; professional jig ensures the focus fixed and makes welding easier without using CCD or microscope.

4. Able to weld with complex, profiled, or tiny letters.

5. Ultra-fine positioning rod makes the welding of tiny corner easier without changing spot position.

6. The whole machine is cooled in air-cooled mode, and the performance is stable.

7. Built-in LED lighting device, microscope built-in cross positioning mark, greatly enhance user experience and reduce work intensity.

| Model | SIE-100W |

| Laser Power | 100W |

| Laser Wavelength | 1064 nm |

| Type of Laser | ND:YAG |

| Max. Single Pulse Energy | 90J |

| Frequency Range | 0.5~20Hz |

| Pulse Width | 0.1~20ms |

| Control System | PC-CNC |

| Observation System | Microscope & CCD monitor |

| Power Consumption | 4KW |

| Cooling System | Air cooling |

| Laser Spot Size | <1.0mm |

| Pump Source | Xenon lamp |

| Electricity Demand | 3 phase 200V(380V)/50HZ ( 60HZ) |

| Packing Size & Weight | Around 117*60*81cm, gross weight around 117 KG |

Suitable for precision casting and welding of small hardware composed of various metal materials, such as jewelry, dentures, clocks, medical treatment, instrumentation, electronic products, mechanical mold processing, automotive and other industries, especially suitable for trimming holes and gold and silver jewelry Spot welding of jewelry, welding of sand holes, repairing joints and parts of claw feet.

Structures

wooden box

Packing size:117*60*81cm

Packing weight:117 KG

SIE-200W Jewellery Laser Weling Machine – Separate Water Chiller

1. Outside chiller is convenient for maintenance and good heat dissipation.

2. High power and high energy ,suitable for high reflective material such as gold ,silver and copper.

3. Touch screen interface to provide convenient control function for users.

4. High quality, 24 hours of continuous working ability, the cavity life is 8 to 10 years, xenon lamp life of more than 8 million times.

5. The user-friendly design, in line with ergonomic, working long hours without fatigue.

6. 10X microscope system based on pioneered the use of high definition CCD observation system to ensure spot effect in appearance.

7. Energy, pulse width, frequency can be adjusted within a wide range to achieve different welding effects.

SIE-200W Jewellery Laser Weling Machine – Separate Water Chiller |

||

| Model: SIE-200W | Maximum laser output power | 200W |

| Welding performance | Laser Wavelength | 1064nm |

| Laser Frequency | 1 – 20Hz | |

| Pulse Width | 0.1-10ms | |

| Cooling power of Chiller | 1 (P) | |

| Maximum single pulse energy | 110J | |

| Welding depth | 0.1mm-2.5mm | |

| Spot size adjustable range | 0.1-1.5mm | |

| Control system | Industrial computer | |

| Observation system | Microscope and red light | |

| Host power consumption | <6KW | |

| Physical characteristics and others | Cooling system | Water Cooling system |

| Host power consumption | 6KW | |

| Voltage | 220V±5%,50Hz,30A | |

| External Dimension | Host Machine 1100*600*1300*mm | 90 Kg |

| Chiller 500*550*750mm | 65 Kg | |

Suitable for precision casting and welding of small hardware composed of various metal materials, such as jewelry, dentures, clocks, medical treatment, instrumentation, electronic products, mechanical mold processing, automotive and other industries, especially suitable for trimming holes and gold and silver jewelry Spot welding of jewelry, welding of sand holes, repairing joints and parts of claw feet.

Structures

wooden box

Host Machine:

Packing size:1100*600*1300mm

Packing weight:90KG

Chiller Machine:

Packing size:500*550*750mm

Packing weight:65KG

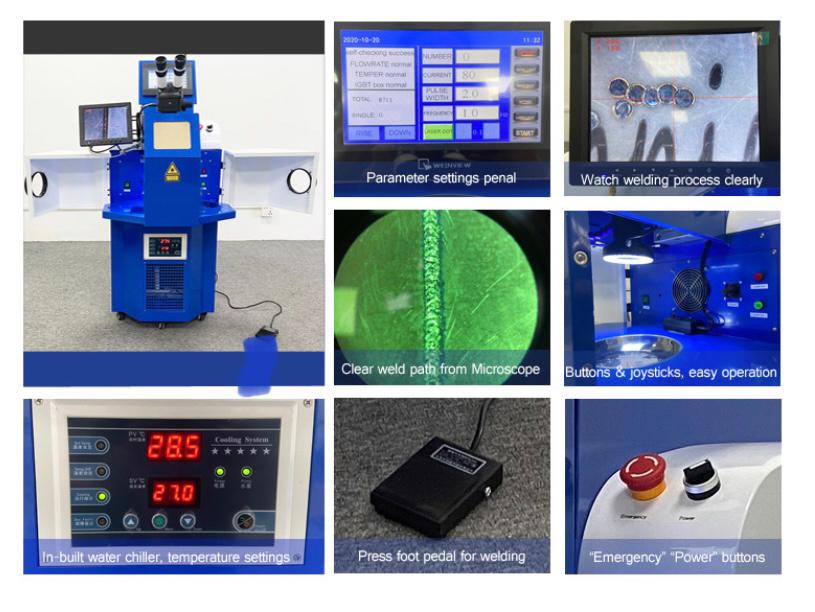

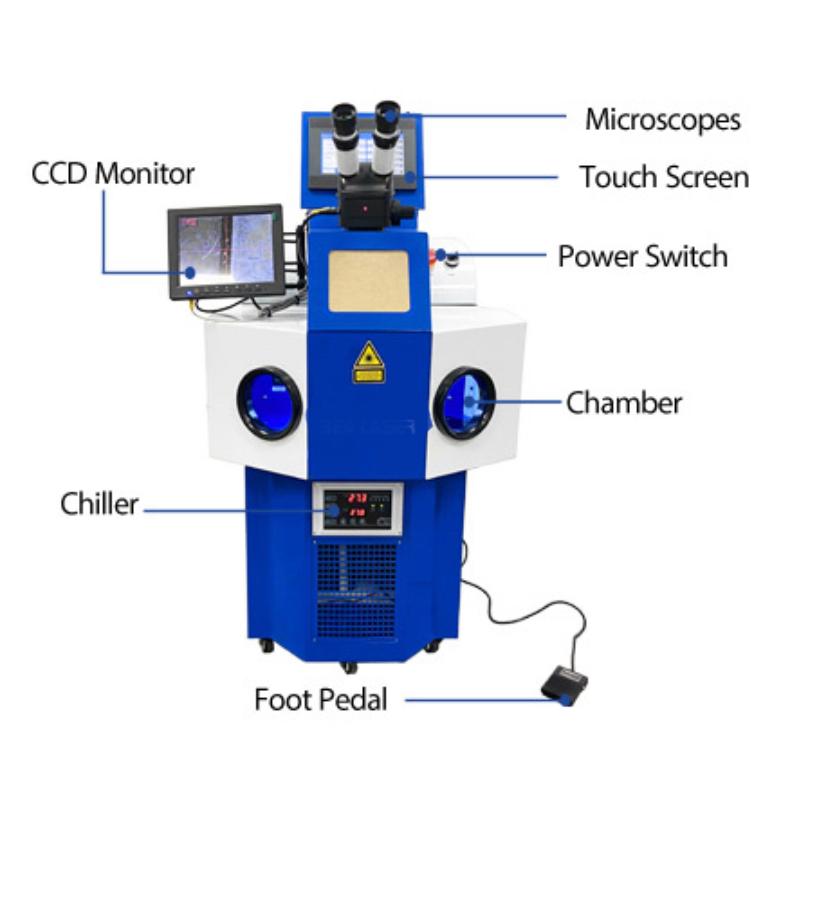

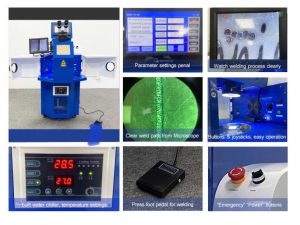

SIE-200W Jewellery Laser Weling Machine – Inbuilt Water Chiller

1. Outside chiller is convenient for maintenance and good heat dissipation.

2. High power and high energy ,suitable for high reflective material such as gold ,silver and copper.

3. Touch screen interface to provide convenient control function for users.

4. High quality, 24 hours of continuous working ability, the cavity life is 8 to 10 years, xenon lamp life of more than 8 million times.

5. The user-friendly design, in line with ergonomic, working long hours without fatigue.

6. 10X microscope system based on pioneered the use of high definition CCD observation system to ensure spot effect in appearance.

7. Energy, pulse width, frequency can be adjusted within a wide range to achieve different welding effects.

|

SIE-200W Jewellery Laser Weling Machine – Inbuilt Water Chiller |

||

| Model: SIE-200W | Maximum laser output power | 200W |

| Welding performance | Laser Wavelength | 1064nm |

| Laser Frequency | 1 – 20Hz | |

| Pulse Width | 0.1-10ms | |

| Cooling power of Chiller | 1 (P) | |

| Maximum single pulse energy | 110J | |

| Welding depth | 0.1mm-2.5mm | |

| Spot size adjustable range | 0.1-1.5mm | |

| Control system | Industrial computer | |

| Observation system | Microscope and red light | |

| Host power consumption | <6KW | |

| Physical characteristics and others | Cooling system | Water Cooling system |

| Host power consumption | 6KW | |

| Voltage | 220V±5%,50Hz,30A | |

| External Dimension | Host Machine 1100*600*1300*mm | 90 Kg |

| Chiller 500*550*750mm | 65 Kg | |

Suitable for precision casting and welding of small hardware composed of various metal materials, such as jewelry, dentures, clocks, medical treatment, instrumentation, electronic products, mechanical mold processing, automotive and other industries, especially suitable for trimming holes and gold and silver jewelry Spot welding of jewelry, welding of sand holes, repairing joints and parts of claw feet.

Structures

wooden box

Host Machine:

Packing size:1100*600*1300mm

Packing weight:90KG

Chiller Machine:

Packing size:500*550*750mm

Packing weight:65KG

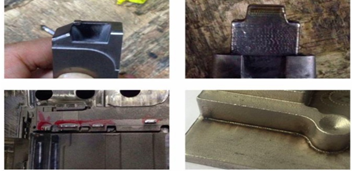

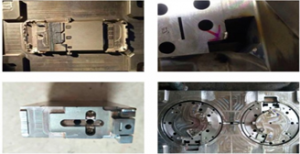

SIE-200W/400W Mold Laser Welding Machine

01. Ceramic converging cavity is corrosion resistant and high temperature resistant, and has 8-10 years service life. The life of xenon lamp is more than 8 million times.

02. Using the most advanced light shielding system to eliminate the irritation to eyes by light during working.

03. Touch screen panel to adjust the parameters, which is simple and convenient.

04. The work bench can be lifted, and moved in three dimensions.

05. The size of light spot can be adjusted.

06. Rotary device optional for cylindrical annular objects repair.

| SIE-200W/400W Mold Laser Welding Machine | ||

| Specifications | SIE-200W | SIE-400W |

| Maximum Laser Power | 200W | 400W |

| The laser wavelength | 1064nm | |

| Condenser Reflector | Imported Ceramic Condensor | |

| Laser Frequency | 1 – 30Hz | |

| The Puls Width | 0.1 – 10Ms | |

| Spot Adjustment Range | 0.3 – 2mm | |

| Aimed at positioning | Microscope | |

| Cooling water machine | 1.5P | |

| Rated Power | 8KW – 220V, 60Hz | |

| Three Dimensional bearing Table | 125X100X300mm ( 150Kg ) | |

| Host Computer | 1000X550X1150mm ( 103Kg ) | |

| 1.5p Cooling water machine | 550X550X850mm ( 80Kg ) | |

It is suitable for precision injection molding, casting, welding mold processing and other industries; all kinds of cold alloy steel, high alloy steel forging, including Nickel welding tool steel, high-grade steel, copper alloys, beryllium copper, high-toughness aluminum and other metal material.

wooden box

1.5p Cooling water machine:550X550X850mm ( 80Kg )